When it comes to prepping a concrete floor for polyurea/aspartic coatings, properly filling cracks and saw-cuts is critical to the long-term success of the flooring system. Improperly filled cracks, either with poor process or product, is a recipe for failure.

Cracks are challenging for a number of reasons. The first reason, is cracks are vents for moisture release from the slab. They also collect moisture, debris and may expand as concrete freezes and thaws – especially areas, such as Minneapolis, where the seasons change so drastically. All of these factors make concrete crack repair challenging.

So how do you repair concrete cracks?

After extensive testing, of all the existing products and processes, we have found a method with proven, long-term results. It comes down to two things; the process and the product.

The Process

First, all cracks must be jackhammered open (or chased). This opens the crack and creates fresh concrete for guaranteed adhesion with our crack filler. This also removes weak spots or soft spots in the path of the cracks in the concrete. Once the cracks have been opened, they are cleaned and vacuumed out to remove dirt and debris.

The Product

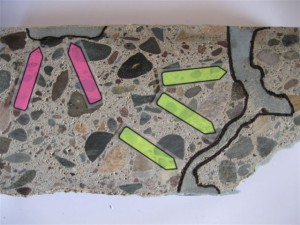

Next, we mix a two part polyurea quick cure crack material. It is then poured / filled into the crack creating a vertical fill. You can see this in top-most picture. We fill the crack so that it is level with top of the concrete floor surface and let it cure.

Once the crack-material is cured, we grind off the excese material and grind the surface so that it is uniform and smooth. It’s now ready for our pure polyurea/aspartic elastomeric coating system.

Contact G-F One Coatings for more information or call us at 612.919.4414

Andy

There is a reason you are the coating guru. 90% of contractors would never go this far.