Question: How thick is your garage floor top coat? We hear this question all the time.

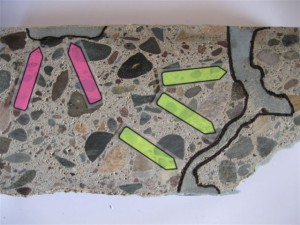

Answer: Every coating manufacture and blender has a recommendation for the thickness of the coating wear surface or D-F-T (Dried Film Thickness). This recommendation is minimal at best and is based on keeping the cost down for the applicator/contractor. We, at G-F One Coatings, know it’s simply not enough.

Result: We only apply, for our Minneapolis, Minnesota area customers, a top coat that has a D-F-T that is twice, 2 times or 100% MORE than the manufacture’s recommendation.

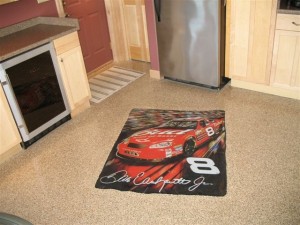

Conclusion: We add more value to our customer’s garage floor project by increasing the thickness of the top coat. Our customers can see the difference. Over time, we hear comments about their appreciation for the “rich, deep, thick top coat” and it’s long term performance.

So we, at G-F One Coatings, named our top coat “the ULTRA TOP COAT.” It’s on every garage floor we do. Call us anytime at 612.919.4414