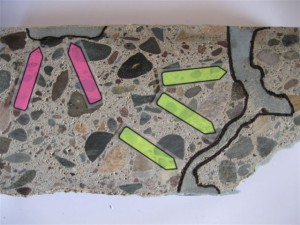

By definition a “pop-out,” in concrete, is the breaking away of the concrete surface leaving a “shallow, conical, depression in the surface.” In Minnesota, it’s usually caused by freeze / thaw cycles, aggregate expansion (a stone in the concrete slab that may be close to the surface), and/or the constant salt attack (think DOT: winter road salts).

Scenario: The typical home owner is naturally concerned about these “pop-outs” in their concrete. They attract dirt, moisture, water, and every year they progressively worsen. Eventually, the owner goes to a store and buys repair material, such as caulk or bagged cement, with the anticipation of it working.

Question: Should you apply a garage coating over a repaired “pop-out?”

Answer: No. The repairs must be removed and replaced. Once a coating is applied, the concrete slab will equalize with moisture (RH – Relative humidity). Moisture over time will deteriorate the “do-it-yourself” repair at the bond point and “pop-out” again.

Question: How should they be repaired and what is the cost?

Answer: All of our repairs are based off industry standards, recommendations, processes and procedures – in layman’s terms, we jackhammer all the damage and repairs out, and fill them with material that is guaranteed to perform and last. The cost can vary based on damage from nothing to $100’s – pending on how much labor and material is required to bring the surface to our standards prior to coating. Every floor is different.

Conclusion: If the old repairs are left in, and the contractor coats over the repair, the failure (which is inevitable) is now the responsibility of the home owner – therefore nullifying any warranty the coating has.

At G-F One Coatings we remove ALL previous repairs, whether they are poured repairs, cement repairs, or caulked (do-it-yourself repairs).

Through years of experience, we have found that if our processes and procedures for repairing “pop-outs” are not properly executed, the failure factor will come to play and the floor will not last. By not following these guidelines, the garage floor coating is simply put at risk.

Feel free to contact us at 612.919.4414